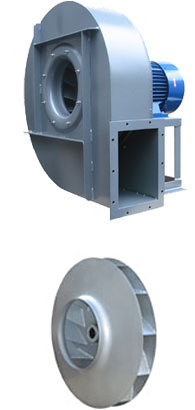

Series U/HPH

The U/HPH series fans are designed to convey air, even containing suspended

solid particles, at temperatures of up to a maximum 80°C.

The U/HPH series fans are designed to convey air, even containing suspended

solid particles, at temperatures of up to a maximum 80°C.This high performance series is generally used in industrial applications requiring high pressure and high flow rates.

The particularly strong steel sheet spiral casings are rimmed, welded and reinforced with profiles. These fans also have a motor support base and the discharge angle can be regulated in 45° steps by rotating either clockwise RD or counter-clockwise LG (see discharge direction table).

The steel sheet impellers with backward-curved blades have been perfectly balanced, both statically and dynamically.

The motors are asynchronous three-phase, 2 poles, B3, with IP55 protection, self-ventilated, designed for continuous service and are UNEL and IEC compliant.

ACCESSORIES

| RP | inlet protection net | |

| GA | intaking vibration-damping joint | |

| RA | intaking joint | |

| RF | inlet flanged fitting | |

| CA | inlet counter-flange | |

| FL | inlet filter | |

| SA | inlet silencer | |

| SF | throttle valve | |

| RM | outlet protection net | |

| GM | feed vibration-damping joint | |

| CM | outlet counter-flange | |

| QT | outlet square-round joint | |

| SM | outlet silencer | |

| TS | discharge plug | |

| PI | inspection door | |

| AV | vibration dampers |

SPECIAL VERSIONS

| AI | made of stainless steel AISI 304 to extract corrosive fumes | |

| AS | anti-spark version in accordance with ANIMA-COAER standards (table NV105) | |

| HZ | manufactured to work at Hz. 60 | |

| HT | conveyed fluid temperature up to a maximum of 250°C (this version is made with longer shaft motor and extra cooling fan) | |

| SB | arrangement 5 with motor type B5 or B3/B5 without motor support base | |

| TH | high protection for use in tropical climate with high degree of humidity | |

| TR | belt drive, 9 or 12 arrangement |